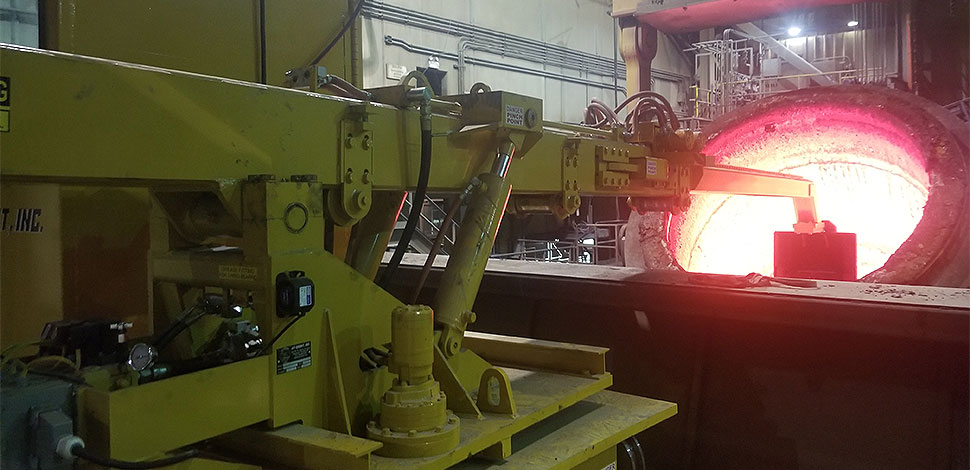

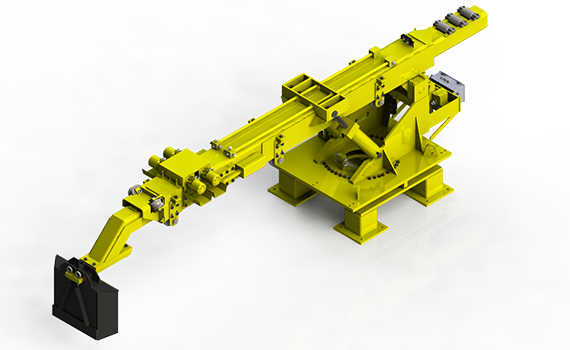

The GSK-150 skimmer utilizes a telescoping boom equipped with a paddle to skim kish/slag off of molten metal. The skimming operation is completed in 2 to 5 minutes depending on the thickness of the kish/slag or dross/solid bath and the location of the skimming unit.

The use of the GSK-150 results in higher iron yield as slag is not poured off. Skimming results in more consistent, higher quality end product than had been obtained using prior methods.

The GSK-150 should be located as close to the vessel as possible. Since each unit is custom made for a specific mill, the reach can be adjusted to meet individual specifications. The boom can be elevated up and down and swings through an arct. The fully hydraulic machine is remote-controlled by one man. The operator usually stands on the floor at vessel height or slightly above.

Two types of paddles are available: steel fabricated or cast. Life of the inexpensive paddle ranges up to two weeks depending on the operator.

The GSK-150 is permanently installed and one is required for each vessel.

Choose Your Color

- Boxed

- Full width

- RTL Version

- LTR Version