Secondary Aluminum

KT-Grant designs and builds specialty-engineered equipment for a variety of Aluminum industry applications.

Furnace Tending and Drossing

KT Grant offers a specialty-engineered mobile or stationary Furnace Tending Machine for drossing and stirring of all sizes of melters and holders. Worker safety is significantly improved by utilizing remote-controlled equipment-eliminating conventional manned operating equipment.

Corundum/dross is removed safely and efficiently while increasing furnace volume. Precise removal of corundum/dross minimizes impact to refractories during clean-out, resulting in less downtime. Furnace is back on line sooner, enabling more metal production and greater profits.

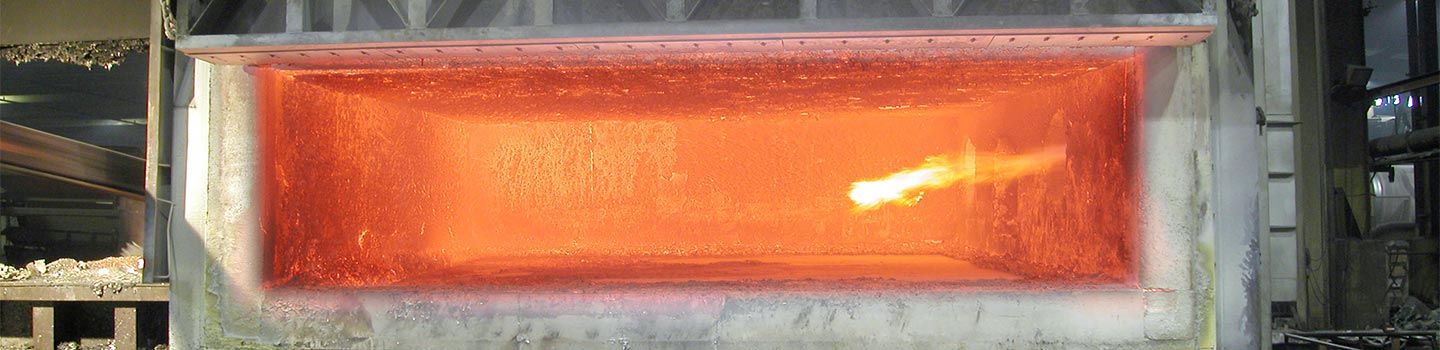

Furnace Hot Cleaning

Worker safety is improved by utilizing remote-controlled equipment, eliminating hours of heavy labor. Maintenance downtime is significantly reduced as furnace clean-out starts once burners are idled.

Corundum is 95%+ removed, increasing furnace volume. Furnace is still hot after corundum removal, minimizing reheat time and yielding significant fuel savings.

Precise removal of corundum minimizes impact to refractories during clean-out, resulting in less downtime. Furnace is back on line within hours, enabling more metal production and greater profits.

Precision Belly Band Repair

Rotary profiling can begin while furnace is still hot. Low-speed high torque drive hub allows for precise corundum removal without impacting refractories.

Oscillating rotary spray head applies monolithic material to replace void from corundum removal. Specialty-designed scraper blade removes all excess rebound. Furnace life is extended and maintenance costs are significantly reduced.

Furnace Refractory Patch/Tearout

Refractory removal using specialty engineered KT-Grant equipment and attachments is performed at a much faster rate. Precession tapblock and launderer lining removal extends refractory life.

Worker safety is significantly improved by utilizing remote controlled equipment, eliminating hours of heavy labor. Furnace clean out starts once burners are idled, significantly reducing maintenance downtime.

Furnace is still hot during refractory patch and tearout, minimizing reheat time and yielding significant fuel savings. Furnace is back on line within hours, enabling more metal production and greater profits.

Complete Furnace Encapsulation

Using the KT-Grant Encapsulation System, contamination from Silica dust is minimized throughout the facility, ensuring worker safety. Our Encapsulation System is built with a structural steel frame around the perimeter of the furnace opening and is covered with a polyethylene lining.

Silica dust is controlled using encapsulation and dual HEPA air filtration system with replacement filters. Crane and heavy equipment operates safely without stopping from poor visibility, eliminating the need for a spotter. Hours of clean-up labor are reduced by containing the silica dust within the containment area. Electrical equipment is not damaged from silica dust exposure.

Product quality is improved with silica dust being contained and minimized in production areas. A clean work environment has a positive effect on employee morale.

Serving Aluminum producers around the globe

Choose Your Color

- Boxed

- Full width

- RTL Version

- LTR Version